目录

ToggleWhy Are Most PCB Multilayer Boards Even in Number?

1.Introduction

2.Balancing the Construction

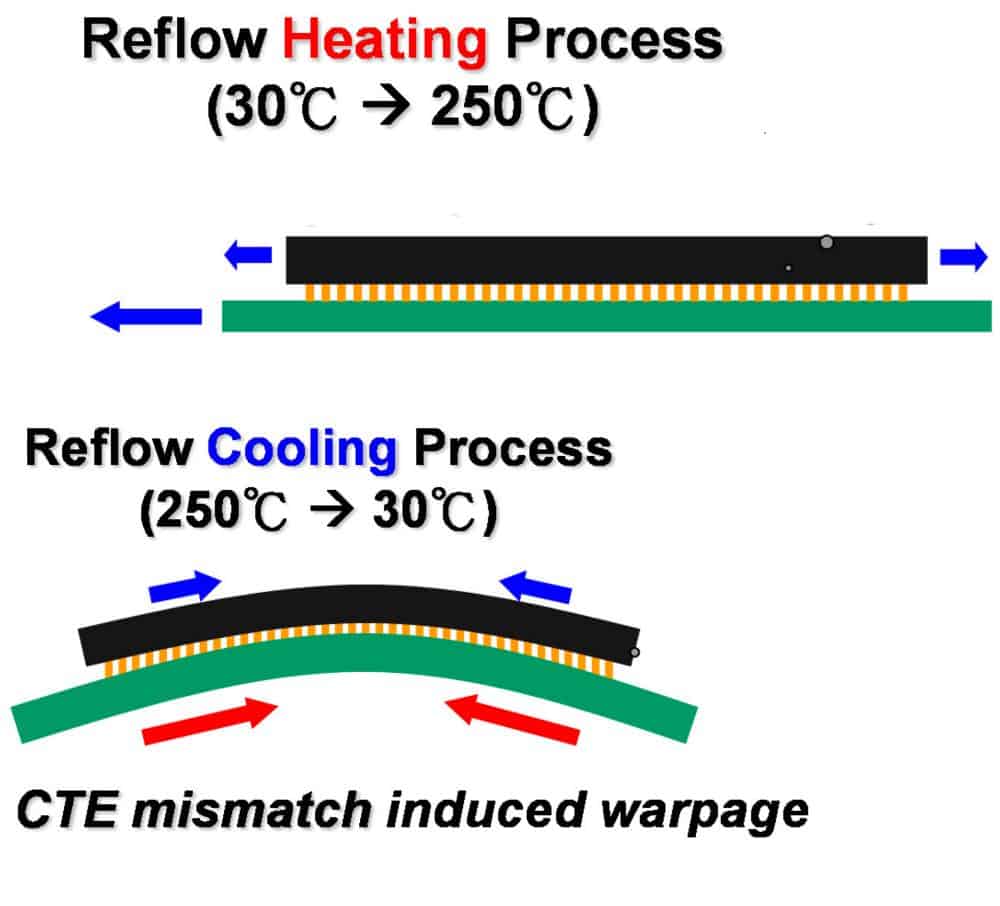

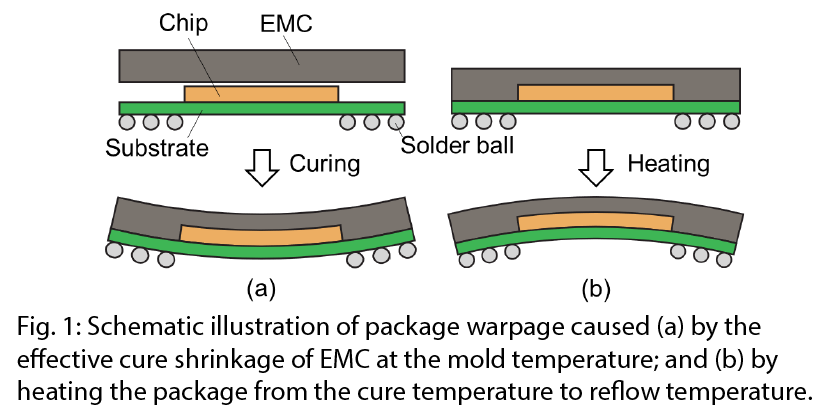

In the realm of Printed Circuit Boards (PCBs), “PCB Multilayer Boards” have emerged as a significant innovation. Of paramount importance in their fabrication is maintaining mechanical stability and balance to ward off potential warping. Typically, warping issues manifest more prevalently in odd-layered boards due to uneven heat distribution and stress during the manufacturing process. This can compromise the structural integrity of these boards, potentially jeopardizing the performance of the device they reside in. Therefore, understanding and implementing methods to retain stability and equilibrium in these PCB Multilayer Boards is crucial. It not only ensures optimal precision and performance but also guarantees the longevity and reliability of these boards, laying the foundation for efficient and effective electronic devices.

3.Concern for Performance

Even numbers of layers help maintain the balance of the entire system. This balance is also critical in terms of thermal expansion and contraction.

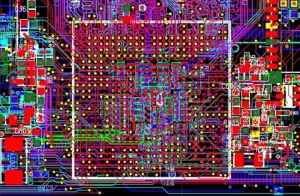

4.Design Consideration and Cost Efficiency

The cost involved in manufacturing even numbered multilayers is less than odd numbered ones. This is due to the industrial process of bonding pairs of layers together.

5.Data Reference

| Odd Layer Count | Even Layer Count |

|---|---|

| Prone to warping | Balanced and stable |

| More expensive to manufacture | Cost-efficient |

| Unbalanced thermal expansion | Balanced thermal expansion |

6.Conclusion

In conclusion, the preference for even number of layers in PCB multilayer boards is primarily due to the need for mechanical and thermal balance, along with cost efficiency in manufacturing.