OUR PCBS

Flexible PCB

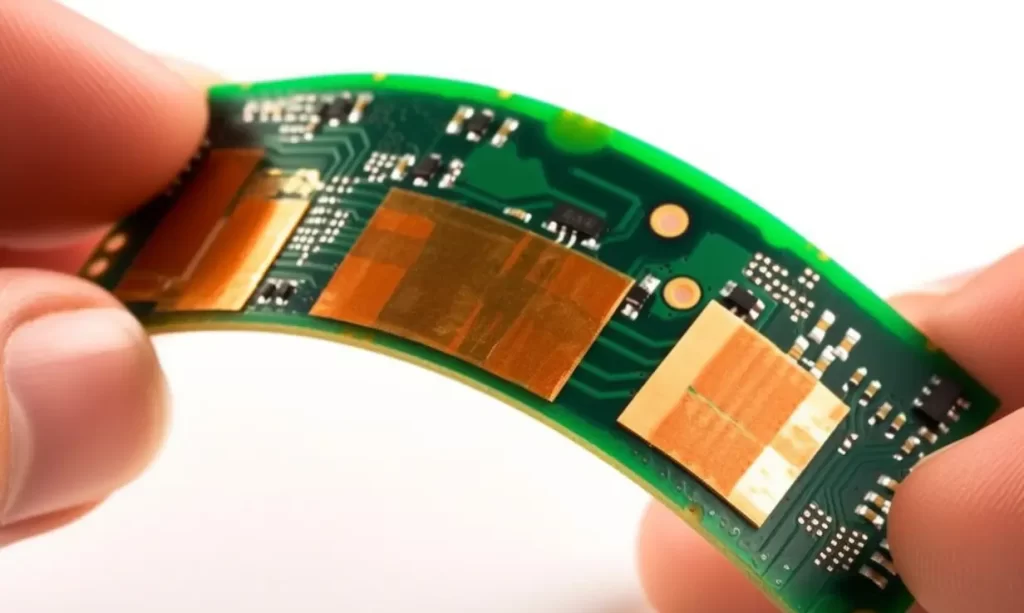

Flexible PCBs, also known as Flex PCBs or FPCs (Flexible Printed Circuits). Flexible PCBs are a type of printed circuit board that, as the name suggests, is designed to be flexible and bendable. Flexible PCBs are constructed using flexible materials like polyimide (PI) or polyester.

Flexible PCB

Characteristics &Manufacturing

Introduction to Flexible Printed Circuit Boards (FPCBs)

Flexible Printed Circuit Boards (FPCBs) are electronic circuit boards made from flexible substrates. They are designed to adapt to various spatial requirements by allowing bending, folding, and flexing. FPCBs are composed of metal foils, such as copper, and flexible polymers like polyimide. These boards are known for their lightweight, flexibility, high-temperature resistance, and excellent bending capabilities.

Manufacturing Process of Flexible Printed Circuit Boards

-

01

Substrate Preparation

Suitable flexible substrates, such as polyimide films, are selected and cleaned to remove surface contaminants.

-

02

Copper Foil Treatment

Thin-film adhesives are applied to the substrate surface, followed by the lamination of copper foils. Enhanced adhesion is achieved through processes like heat pressing or electroless copper plating.

-

03

Patterning

Photolithography techniques are employed to transfer the designed circuit pattern onto the copper foil, creating conductive pathways.

-

04

Electroplating

An electroplating process is utilized to deposit a protective metal layer, such as nickel or gold, onto the conductive pathways. This step enhances conductivity and corrosion resistance.

-

05

Panelization

FPCBs are cut into the desired shape based on design requirements and undergo surface treatments, including edge plating and hole drilling. Component Assembly: Electronic components and connectors are either soldered or bonded onto the FPCBs.

-

06

Component Assembly

Electronic components and connectors are either soldered or bonded onto the FPCBs.

-

07

Testing and Inspection

The manufactured FPCBs undergo electrical testing and reliability inspections to ensure compliance with specifications.

-

08

Packaging and Delivery

The finished FPCBs are packaged according to customer requirements and delivered accordingly.