OUR PCBS

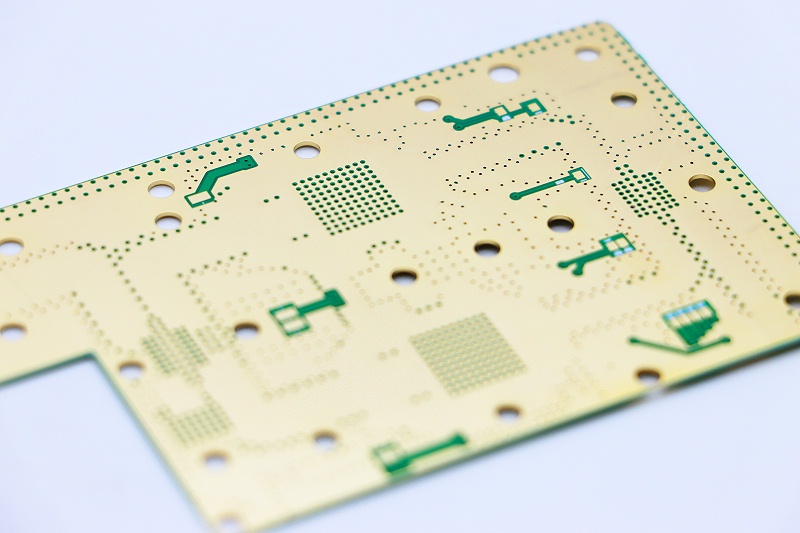

ROGERS PCB

Rogers PCB materials offer high-frequency performance and reliability.

You'll like it.

-

Rogers PCB

-

High Frequency PCB

-

High Sepeed PCB

-

2 Layer Board

-

4 Layer Board

ROGERS PCB

Characteristics &Manufacturing

Rogers PCB Materials (Rogers PCB) Introduction

Rogers Corporation specializes in high-performance PCBs, known for excellent signal integrity, thermal management, and efficiency. Ideal for demanding sectors like telecom and aerospace, Rogers PCBs ensure reliability and quality in advanced electronic applications.

Rogers Printed Circuit Board Manufacturing Process

-

01

Material Selection

Choose appropriate substrate materials for the application, with Rogers PCBs often utilizing materials like PTFE and ceramic-filled composites.

-

02

Design and Layout

Use CAD (Computer-Aided Design) software for PCB design and layout, which is crucial for ensuring circuit performance and reliability.

-

03

Photolithography Process

Apply a photoresist to the conductive material (usually copper foil) and use photolithography techniques to form the circuit pattern.

-

04

Etching

Use a chemical solution to etch away the unprotected copper, creating precise circuit patterns.

-

05

Drilling

Drill holes in the PCB for mounting pins and connecting multiple layers.

-

06

Plating and Surface Finishing

Copper plating of the drilled holes and circuits, and other surface finishes such as Hot Air Solder Leveling (HASL) or Electroless Nickel Immersion Gold (ENIG).

-

07

Lamination for Multilayer

For multilayer PCBs, different layers are laminated together through a thermal pressing process.

-

08

Cutting and Shaping

Cut the large panel into individual PCB sizes or perform necessary shape processing.

-

09

Component Assembly

Install electronic components onto the PCB using Surface Mount Technology (SMT) or through-hole technology.

-

10

Testing and Inspection

Perform various electrical tests and quality inspections on the completed PCB to ensure it meets design and performance specifications.

-

11

Packaging and Shipping

Package the qualified PCBs and prepare them for shipment to customers.