OUR PCBS

Metal PCB

This type of printed circuit board (PCB) combines the durability of metal with the efficient and cost-effective printing process of traditional PCBs.

You'll like it.

-

Rogers PCB

-

High Frequency PCB

-

High Sepeed PCB

-

2 Layer Board

-

4 Layer Board

Metal PCB

Characteristics &Manufacturing

Introduction to Metal PCB

Metal PCB, also known as Metal Core PCB (MCPCB), is a type of printed circuit board where the base material is made of metal instead of the traditional glass fiber reinforced resin (FR-4). Metal PCBs offer excellent heat dissipation capabilities, good mechanical strength, and electromagnetic shielding, making them widely used in high-power electronic devices, LED lighting, and automotive electronics. Metal PCBs effectively reduce circuit temperatures, thereby improving the operational stability and reliability of electronic components.

Manufacturing Process of Metal PCB

-

01

Material Selection

Suitable metal materials are chosen for the Metal PCB, commonly including aluminum (Al) and copper (Cu). Material selection depends on factors such as heat dissipation requirements, electrical performance, and cost.

-

02

Material Preparation

The selected metal material undergoes pre-processing, such as cleaning, removal of oxides, and application of protective coatings. This ensures surface smoothness and cleanliness of the material.

-

03

Substrate Preparation

The metal base material is cut into the desired size and shape. Mechanical cutting or CNC cutting methods are typically used.

-

04

Copper Foil Lamination

Copper foil is laminated onto the surface of the metal substrate to form the circuit layer. The copper foil is secured through compression or heat bonding.

-

05

Pattern Formation

Circuit patterns are transferred onto the copper foil layer using photolithography techniques. This involves applying photoresist, exposure, and development steps to form the circuit patterns.

-

06

Copper Etching

Chemical etching is used to remove the unprotected copper foil, leaving behind the desired conductive traces and circuit structures.

-

07

Surface Treatment

Surface treatment is performed on the metal substrate, including cleaning, oxide removal, and application of corrosion-resistant coatings. This enhances the corrosion resistance and solderability of the metal substrate.

-

08

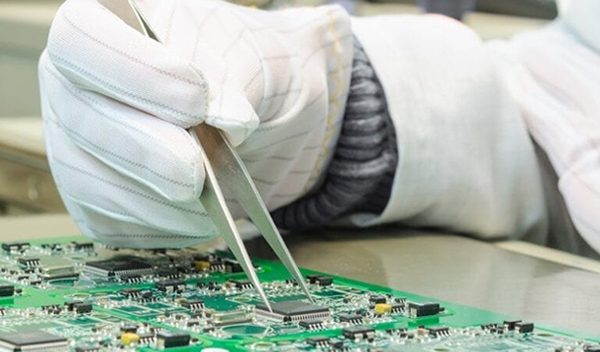

Component Assembly

Electronic components are mounted on the Metal PCB through soldering or surface mounting techniques.

-

09

Soldering

Suitable soldering methods, such as surface mount technology (SMT) or through-hole soldering, are employed to connect electronic components to the Metal PCB.

-

10

Testing and Validation

Electrical testing and performance validation are conducted on the completed Metal PCB to ensure it meets the design requirements and application needs.